Developments

Solid oxide fuel cell (SOFC) product portfolio

Solid Oxide Electrolyser Cells (SOEC)

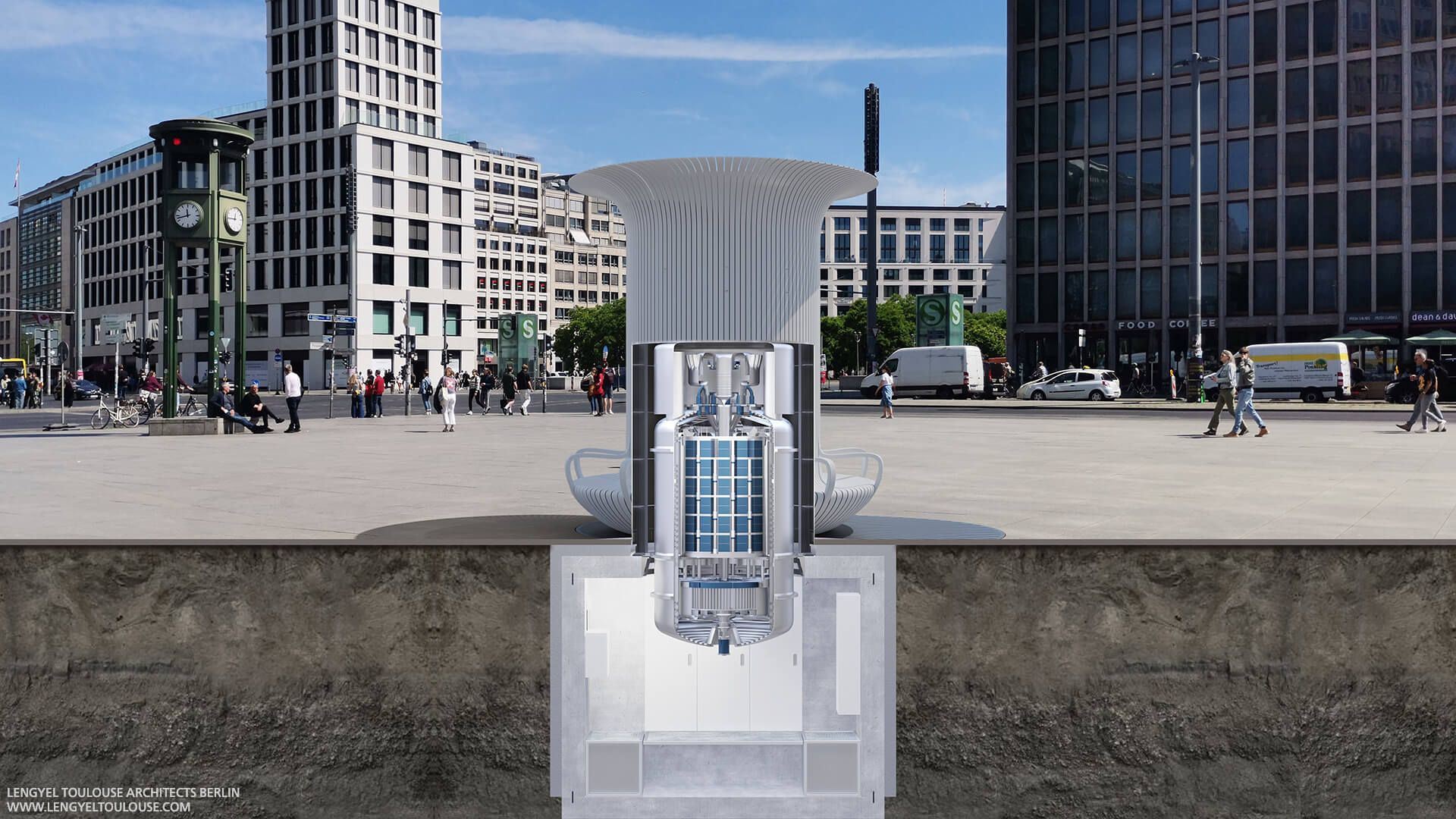

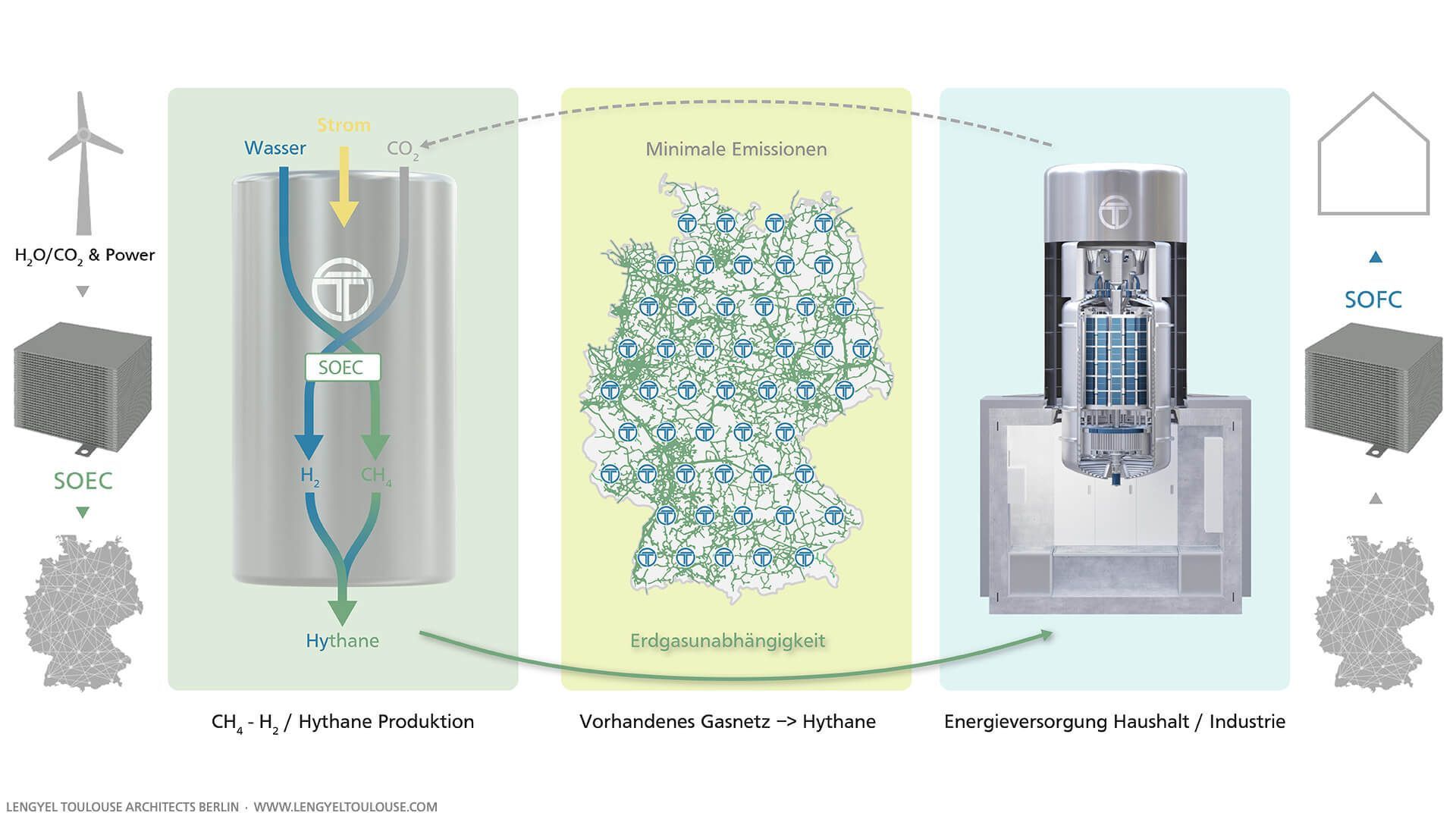

By reversing the process, the fuel cell stack developed by ITKS can also be used as a solid oxide electrolyzer cell to produce hydrogen. This opens up another possible application for the T-Cell.

By applying a voltage to an electrolyte that conducts oxygen ions, water vapor is split into hydrogen and oxygen. In addition, co-electrolysis operation offers the opportunity to use unavoidable, climate-damaging CO₂ to produce climate-neutral products. To do this, water and CO₂ are split into oxygen, hydrogen and carbon monoxide.

At the end, the electrical energy is converted into a synthesis gas, which is...stored, but above all can also be converted into higher quality products.

Stack production

Heart of the fuel cell

The stack is the heart of a fuel cell. It consists of an array of cells connected in series that convert the chemical energy of hydrogen and oxygen into electrical energy.

Production at the highest level

Stack production requires a high level of precision and know-how. Our company has many years of experience in the production of fuel cells. We use state-of-the-art production facilities and processes to ensure high quality and efficiency.

Innovative processes

We use innovative processes to further optimize the production of our stacks. These include, for example, new manufacturing techniques and materials that enable higher power density and service life of the stacks.

Future-proof technology

Our stack production is geared towards future requirements. We are able to produce stacks for a wide range of applications, including stationary and mobile applications.

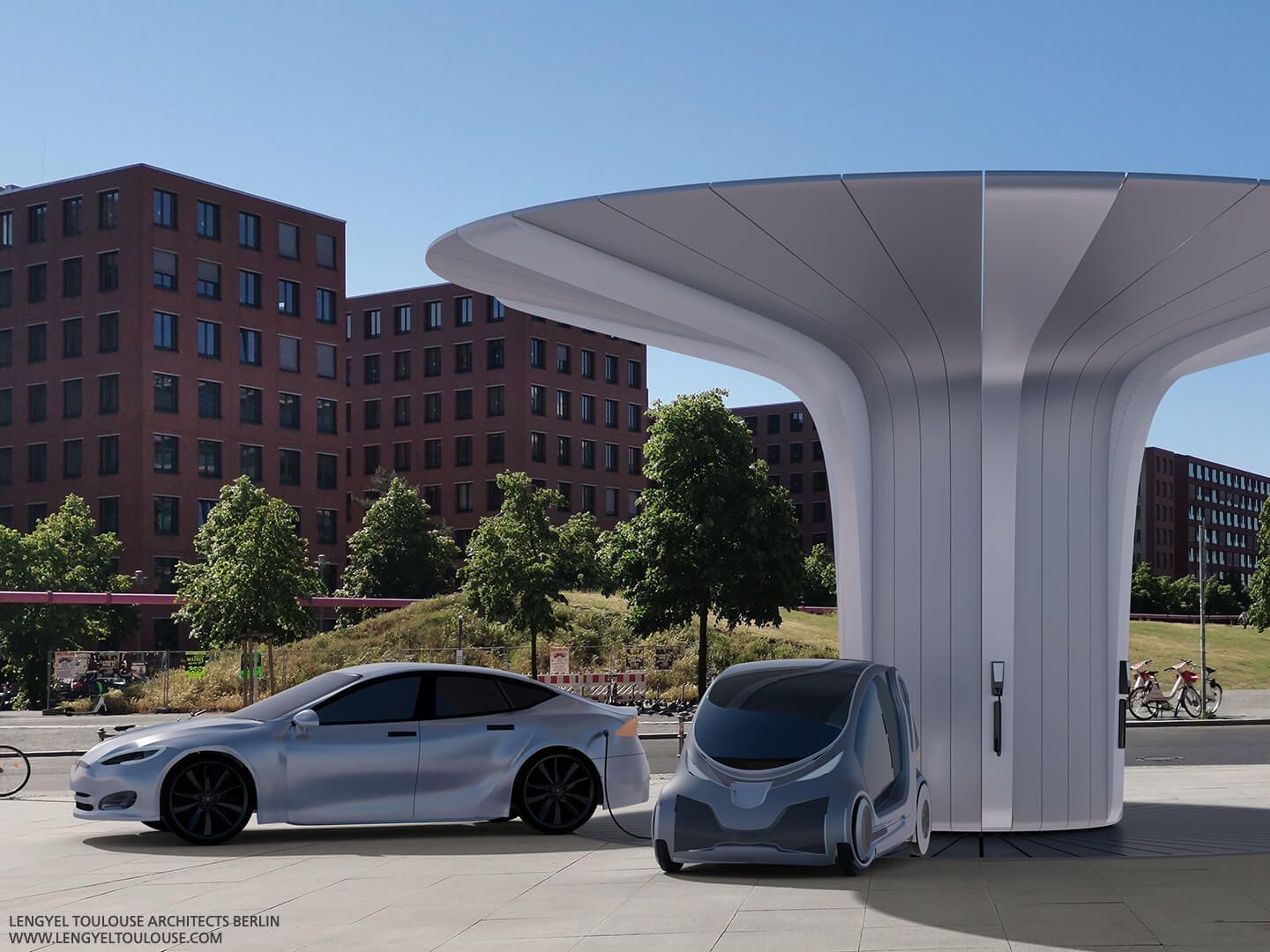

Mobile use

What is T-Cell Mobile?

Presentation of the T-Cell Mobil and its possible applications.

The T-Cell is also able to act as an energy source for train drive units, thus offering a sustainable and efficient alternative to conventional diesel drives.

Due to the high overall efficiency of up to 97% and the use of CO₂ Neutral fuels such as ammonia, the T-Cell can provide a significant performance advantage and cost savings in a rail application. The flexible integration of different fuels also allows adaptation to different requirements and markets.

The T-Cell not only offers ecological advantages by avoiding fossil fuels, but also economic advantages through its efficiency and the potential savings in operating costs.

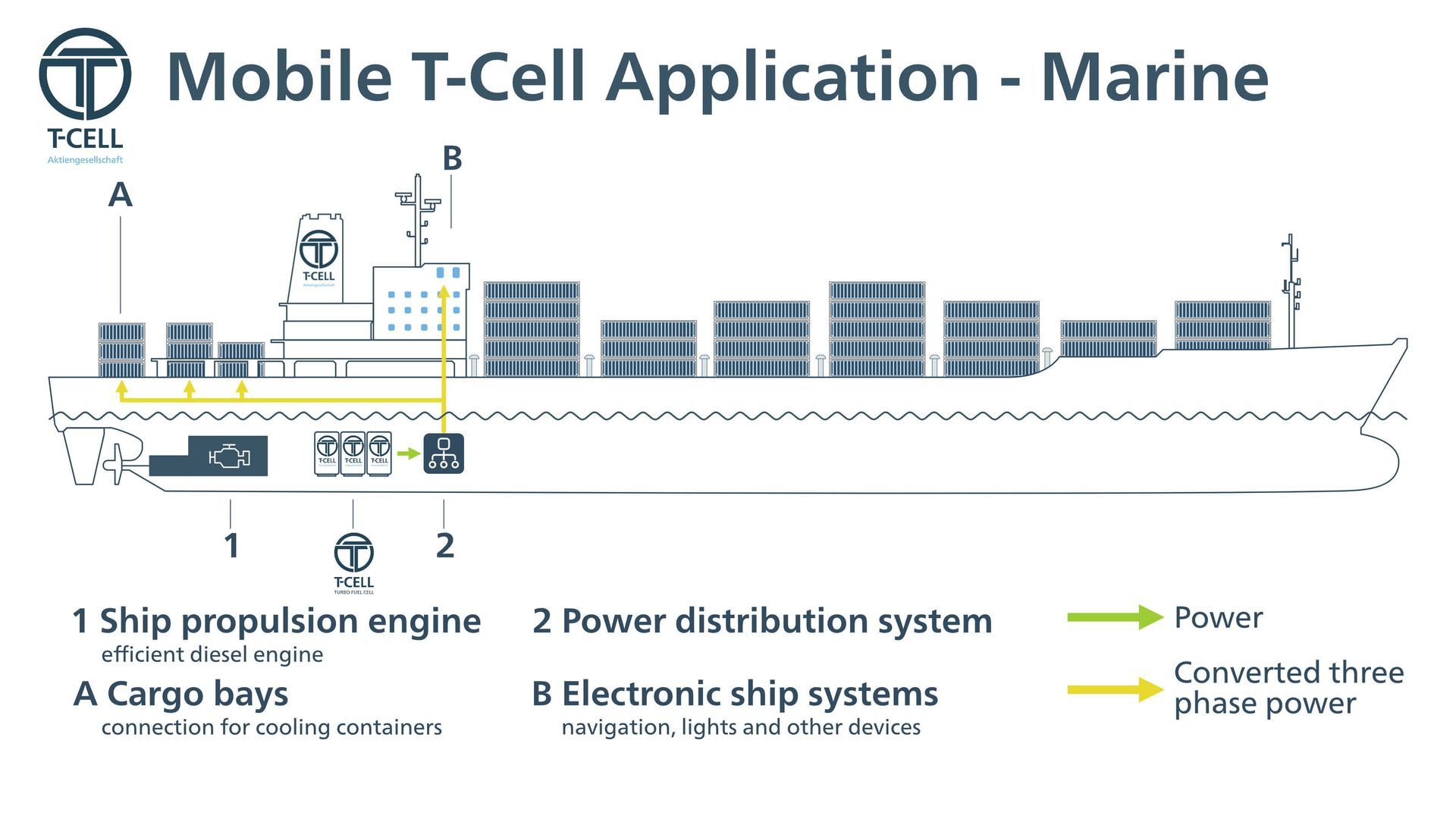

As an auxiliary power unit, the T-Cell offers an ideal solution for use on ships. As an environmentally friendly energy source, it can supply on-board systems and refrigerated containers with electricity, thus reducing the need for fossil fuels. It is extremely reliable and powerful.

Thanks to its compact design, it requires very little space and thus enables flexible integration into existing ship systems. By using the T-Cell as an auxiliary power unit, operating costs can be reduced while protecting the environment. Global freight shipping can thus become greener!